Edge banding is a thin strip of material applied to the raw edges of plywood, MDF, or particleboard. It solves three key problems:

- Safety: Rough edges can splinter or cause injuries.

- Durability: Protects against moisture, scratches, and daily wear.

- Aesthetics: Transforms unfinished edges into polished, professional surfaces.

Whether you’re building cabinets, shelves, or countertops, edge banding ensures your project looks and feels high-quality.

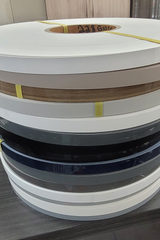

Types of Edge Banding Materials (and When to Use Them)

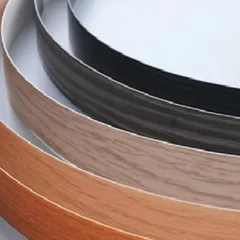

1. Wood Veneer Edge Banding

- Best For: Furniture, cabinets, and projects needing a natural wood look.

- Pros: Stainable, eco-friendly, matches oak/maple/mahogany furniture.

- Cons: Not waterproof; avoid in bathrooms.

Explore types of wood veneer or learn about different wood veneer edge banding options for your project.

2. PVC Edge Banding

- Best For: Kitchens, bathrooms, and high-moisture areas.

- Pros: Waterproof, affordable, easy to clean.

- Cons: Limited heat resistance.

3. ABS Edge Banding

- Best For: High-heat zones (near stoves) and eco-conscious projects.

- Pros: Recyclable, heat-resistant, durable.

- Cons: Higher cost than PVC.

4. Melamine Edge Banding

- Best For: Budget-friendly shelves and office furniture.

- Pros: Pre-glued, easy to apply, scratch-resistant.

- Cons: Less durable than PVC/ABS.

5. T-Molding Edge Banding

- Best For: Transitioning between surfaces (e.g., countertops to floors).

- Pros: Hides gaps, protects edges.

- Cons: Requires specialized installation.

6. Metal Edge Banding

- Best For: Industrial designs or heavy-use surfaces.

- Pros: Extremely durable, modern look.

- Cons: Harder to trim.

| Material | Best For | Waterproof? | Heat-Resistant? | Cost |

|---|---|---|---|---|

| Wood Veneer | Furniture | No | No | $$ |

| PVC | Kitchens | Yes | No | $ |

| ABS | High-heat areas | Yes | Yes | $$$ |

How to Choose the Right Edge Banding

Thickness & Width Guide

- Standard Panels (18mm): Use 22mm-wide banding for full coverage.

- Thick Countertops (25mm+): Opt for 30mm-wide PVC or ABS

How Edge Banding is Applied: DIY vs. Pro Tools

DIY Method (Iron-On)

- Trim: Cut banding slightly longer than the edge.

- Heat: Use a household iron (medium heat) to activate adhesive.

- Press: Roll firmly to remove bubbles.

- Trim Excess: Use a utility knife for clean edges.

⚠️ Pro Tip: Avoid scorching veneer—test heat on a scrap piece first!

Professional Method (Edge Banding Machine)

- Best For: Large projects or thick materials (e.g., countertops).

- Tools Needed: Automatic trimmer, adhesive applicator.

FAQs: Answering Top User Questions

1. Can I use a regular iron for edge banding?

Yes, but set it to medium heat (300°F). For best results, use an edge banding iron

2. Is edge banding necessary for painted furniture?

Yes! It prevents paint from chipping off rough edges

3. How do I fix peeling edge banding?

Reheat the area with an iron and press firmly. For stubborn spots, add wood glue

Ready to Start Your Project?

Explore our curated selection of edge banding materials:

- Veneer Edge Banding Natural finishes for cabinets and furniture.

- PVC Edge Banding for kitchens and bathrooms.

- Metal Edge Banding: modern high-end looks.

Need Help? Contact our experts for personalized advice!

Recent Blogs

-

ULTRAPAN luxury polymer panel - modern kitchen cabinets material

Read more -

How to Choose the Right Wood Board for Your Woodworking Project

Read more -

The Importance of Boards in Various Sectors

Read more -

What is a Laminate Sheet – Types and Uses

Read more -

Understanding the Differences: ABS vs PVC Edge Banding

Read more -

What is Edge Banding? Beginner Guide to Safe, & Professional Finishes

Read more